01 简述/Introduction

钛及钛合金的比重几乎是铁金属的一半,具有低密度、良好的耐腐蚀能力、高比强度以及令人满意的生物兼容性,在航空、航天、化工、生物医学等领域得到广泛的应用,并为人类社会带来巨大的经济效益,尤其是在人体植入物取代失效的骨骼 如假牙、牙根、义肢等骨骼补强,是一种能够造福了人类的好材料。/ Titanium and titanium alloys account for almost half of density of iron. They have low density, good corrosion resistance, high specific strength and satisfactory biocompatibility. They are widely used in aviation, aerospace, chemical industry, biomedicine and other fields, and bring huge economic benefits to human society, especially in replacing invalid bones such as dentures, roots and prostheses with human implants. Titanium and titanium alloys are good material that can benefit mankind.

然而,钛及钛合在粉末冶金技术上最大的难题是如何减少或避免氧化的发生,根据吉布斯自由能(Gibbs Free Energy)所绘制的氧化物的标准生成自由能—温度图的观察,想要把氧化的钛或钛合金还原回金属,所付出的代价极为庞大不符合经济效益,这也是钛及钛合在粉末冶金制程上的劣势,与铁系家族材料相比,就失去了加工成本的优势。无怪乎钛与钛合金在传统块材加工的优势比起粉末冶金要高许多,这是粉末冶金从业首先要知悉的。/ However, the most difficult problem in powder llurgy is how to reduce or avoid the occurrence of oxidation of titanium and titanium alloys. According to the observation of the standard free energy-temperature diagram of oxides drawn by Gibbs Free Energy, the cost of reducing oxidized titanium or titanium alloys back to l is enormous, which is not in line with the economic benefits. This is the reason that titanium and titanium are combined in powder also. The disadvantage of llurgical process, compared with iron family materials, lost the advantage of processing cost. It is no wonder that the advantages of titanium and titanium alloys in traditional bulk processing are much higher than those of powder llurgy, which is the first thing that powder llurgy practitioners should know.

02 注意要点/Points for Attention

钛及钛合金的粉末注射成形产品要能成功,必须按照以下方式着手:/In order to succeed in powder injection molding of titanium and titanium alloys, the following methods must be adopted:

起始粉末的氧含量控制,必须要把粉末的氧含量控制在3000 ppm以下,最好当然是控制在小于1000 ppm;购买低氧含量的粉末才有良品产出的机会;/If we hope control the oxygen content of the initial powder, the oxygen content of the powder must be controlled below 3000 ppm, preferably less than 1000 ppm, and only when the powder with low oxygen content is purchased can the good product be produced.

制程中必须注意到与氧气反应的机会,混料粉末与黏结剂必须在保护气氛下进行、注射成形尽可能减少加温与保温时间的减少、脱脂过程采用还原性气体保护或改用还原性草酸脱脂、脱脂后立刻进行真空或是保护气氛烧结;In the process of degreasing, attention must be paid to the opportunity of reaction with oxygen. Mixture powder and binder must be carried out in a protective atmosphere, injection molding must minimize the reduction of heating and holding time, degreasing process should be protected by reducing gas or replaced by reducing oxalic acid degreasing, and sintering in vacuum or protective atmosphere immediately after degreasing.

烧结承烧板与支架系统的设计,利用不易被钛抢氧的氧化锆板、小块海绵钛牺牲摆设协助烧结系统内氧含量降低;The design of sintered bearing plate and support system uses zirconia plate and small sponge titanium sacrificial arrangement which are not easy to be preempted by titanium to help reduce the oxygen content in sintering system.

在材料粉末系统中加入抢氧的的成分,如镁,但这样可能造钛及钛合金的成分变异,烧结后钛及钛合金强度变差。/The addition of oxygen-rushing components, such as magnesium, in the material powder system may lead to variations in the composition of titanium and titanium alloys, and worse strength of titanium and titanium alloys after sintering.

以下,我们将根据过去的制造经验,分享一些技术上的注意事项给大家。/Following, we will share some technical considerations d on past manufacturing experience.

2.1粉末原料选择/ Selection of Powder

使用低氧含量的粉末是钛及钛合金注射成形的首选,这意味着粉末使用的是气雾化法的球行粉末较为适合,气雾化粉因为使用惰性气体加压冷却,粉末颗粒较大而圆,氧含量较低,目前以美国的卡本特与英国的山特维克为主,粉末粒径以d50=10~12um为宜,过于细小的粉末容易氧化,制程过程也较危险;水雾化法过于细小和粗糙,机械破碎法的颗粒较大,都不适合注射成形制程;另一派说法支持以氢化钛粉除氢,并以高能量如等离子破碎圆化粉末,虽然取得原料成本很低,但是专利的纠纷和控制设备的投资颇高,目前尚未普及。/ The use of powders with low oxygen content is the preferred choice for injection molding of titanium and titanium alloys, which means that the powders are spherical powders by aerosol method, which are cooled under pressure by inert gas. The powders are large and round with low oxygen content. At present, the main powders are Carpenter in the United States and Sandvik in the United Kingdom. The particle size of powders is suitable for d50=10~12um, which is too small. Powder is easy to oxidize and the process is dangerous; water atomization method is too small and rough, and the particle size of mechanical crushing method is too large to be suitable for injection molding process; another theory supports the use of titanium hydride (HTi) powder to remove hydrogen and to crush round powder with high energy such as plasma treatment. Although the cost of obtaining raw materials is very low, patent disputes and investment in control equipment are quite high, which is not yet universal.

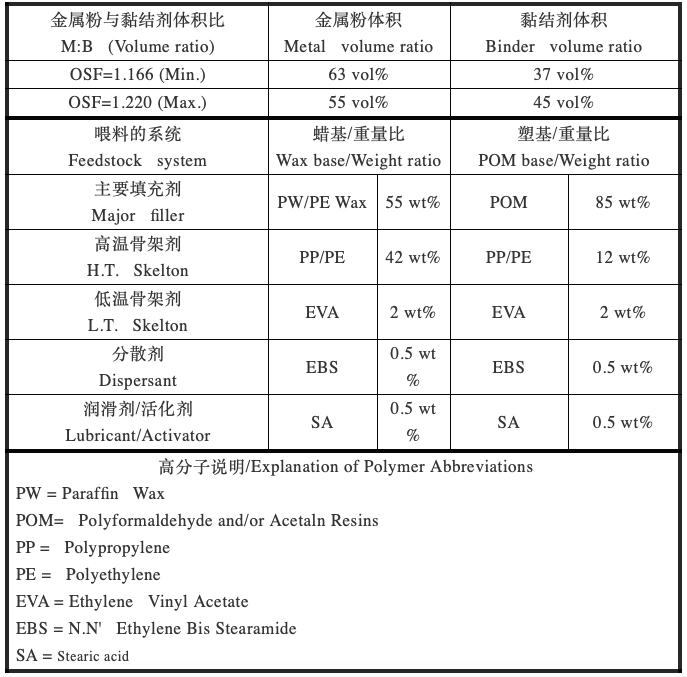

2.2黏结剂配方/ Binder formula

调配钛及钛合金有两种喂料系统,建议如下表1所示,配方比以收缩率范围1.166~1.220之间较佳。这些配方都是市面上已经公开的。/Titanium and titanium alloys have two feedstock systems. It is suggested that the formula is better than that in the range of Shrinkage from 1.166 to 1.220 as shown in Table 1 below. These formulations are already on the market.

表1.钛及钛合金的配方调配表/Table 1: Binder formulation of Titanium and Titanium Alloys

OSF = Oversize Shrinkage Factor

由于钛及钛合金的氧化问题,建议配方比中的金属体积不高于63%,以避免喂料调配与注射成形过程粉末的摩擦可能,一旦摩擦温度过高导致氧化的可能性增加。/ Due to the oxidation of titanium and titanium alloys, it is suggested that the volume of l in the formulation ratio should not exceed 63%, so as to avoid the possibility of friction between powder in injection molding and feedstock mixing. Once the friction temperature is too high, the possibility of oxidation will increase.

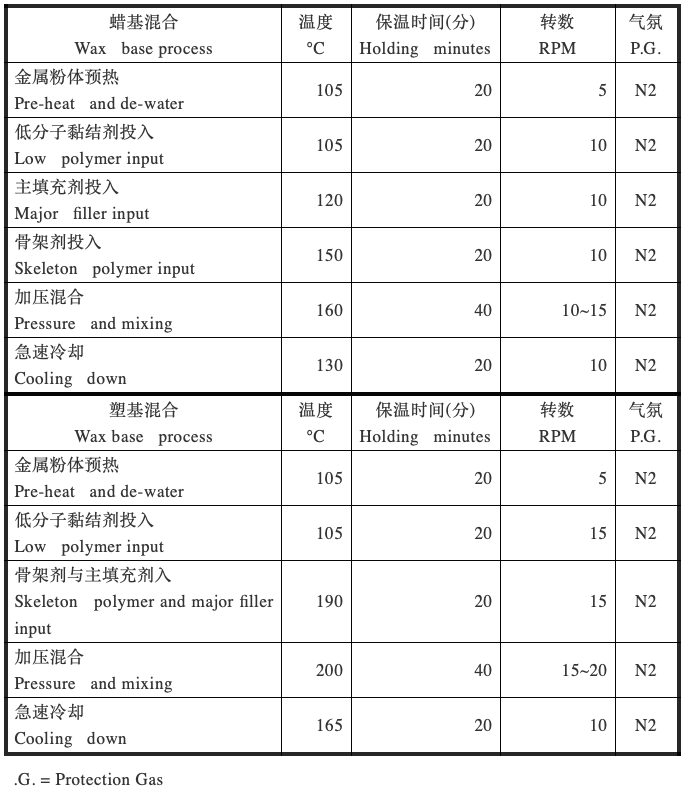

2.3喂料调配的注意事项/ Notices for feedstock preparation

特别要注意控制混合喂料的投入材料顺序和温度的控制,请见表2的描述。两种喂料的混合程序建议。注意到混合过程一定要以保护气氛进行氧气的排除,注意到所有高分子黏结剂颗粒或是粉末一定进行烘干,确保没有水分,难以烘干的蜡和硬脂酸等低分子黏结剂,建议以低温真空去除水分。/Particular attention should be paid to the control of the order of feedstock materials and the temperature of mixed feedstock, as described in Table 2. The mixing procedure of the two kinds of feedstock is suggested. It is noticed that the mixing process must be carried out in order to protect the atmosphere for oxygen removal. It is also noted that all macromolecule binder particles or powders must be dried to ensure that there is no moisture, wax and stearic acid, which are difficult to dry, are low molecular binders. It is suggested that water be removed by low temperature vacuum.

表2. 喂料的混合程序建议/ Suggestions on feedstock mixing procedure

03 主要制程/ Major process

一但喂料完成一直到注射成形,这是整个粉末最安全的状态,可以暴露在空气中作业无妨,但是在注射过程的加热一定要注意不要让喂料停留在炮管中太久。注射塑基喂料过程一但故障、调机,一定要把射嘴温度和最高温区域设定在10分钟不工作就要将温度切断,使喂料低于150℃。/ Once the feedstock is completed until injection molding, it is the safest state of the whole powder, which can be exposed to air, but during the heating of the injection process, care must be taken not to let the feedstock stay in the barrel for too long. Once the injection process of plastic- d feedstock fails and adjusts the machine, it is necessary to set the temperature of the nozzle and the maximum temperature area in 10 minutes and cut off the temperature if not working, so that the feeding temperature is lower than 150℃.

钛及钛合金注射成形后生坯与一般金属材料的喂料无异,可以放置在空气中。钛及钛合金粉末包覆了黏结剂之后,黏结剂可以有效的阻隔空气中的氧。然后进行脱脂后,不论是溶剂脱脂还是还原性的草酸脱脂(不建议使用强氧化的硝酸脱脂方式),首先要确保离开炉体的温度要低于50℃以下,以确保氧化不会发生,脱脂后的棕坯是多孔性的,非常容易与空气中的氧反应,请注意。棕坯放置在外的时间越短越好,尽快的进入烧结系统中。/ Titanium and titanium alloy billets after injection molding are no different from those of common l materials and can be placed in air. Titanium and titanium alloy powder coated with binder can effectively block oxygen in the air. After degreasing, whether solvent degreasing or reductive oxalic acid degreasing (strongly oxidized nitric acid degreasing is not recommended), first of all, to ensure that the temperature leaving the furnace should be below 50℃. Celsius to ensure that oxidation does not occur, the degreased Brown billet is porous, very easy to react with oxygen in the air, please note. The shorter the time of placing the brown billet outside, the better, it will enter the sintering system as soon as possible.

烧结的承烧板以及烧结盒的设计是重要的,由于钛及钛合金的氧亲和性高,在高温状态甚至能够夺取氧化铝中的氧,因此陶瓷承烧板建议采用氧化锆板,但不要选择碳化或氮化的材料,钛及钛合金也喜欢亲和碳元素和氮元素。在過去的燒結經驗中,在燒結箱中放置海綿鈦作為搶氧的犧牲塊,這是有效但是降低了燒結爐的效率,每次要消耗不少的海綿鈦之外,佔據的空間和消耗的熱量都是負面的。/ The design of sintered supporting plate and sintering box is very important. Because titanium and titanium alloys have high oxygen affinity, they can even capture oxygen in alumina (Al2O3) at high temperature. Therefore, zirconia plate (ZrO2) is recommended for ceramic bearing plate, but the material of carbonization or nitriding should not be chosen. Titanium and titanium alloys also like affinity for carbon and nitrogen elements. In the past sintering experience, the placement of titanium sponge in the sintering box as a sacrificial block of oxygen grabbing is effective but reduces the efficiency of the sintering furnace. It consumes a lot of titanium sponge at a time, occupying space and consuming heat are negative.

以上是在制作钛及钛合金粉末注射成形的经验分享,操作者一定要谨慎,纯钛的细粉状态是高危险性,这些有色金属(密度<4.5g/c.c.)都具有粉尘爆炸的风险,虽然钛及钛合金已经算是活性最低的有色金属。/ The above experience is shared in the production of titanium and titanium alloy powder injection molding. Operators must be cautious. The state of pure titanium powder is high risk. These non-ferrous ls (density < 4.5g/c.c.) all have the risk of dust explosion, although titanium and titanium alloys are the least active non-ferrous ls.